Photocatalytic Technology

How Photocatalytic Degradation Works

Photocatalysis uses semiconductor materials, such as titanium dioxide (TiO₂), which are activated by light – typically ultraviolet radiation, and ideally sunlight. When a photon with sufficient energy strikes the surface of the material, pairs of charge carriers are generated – electrons and positively charged “holes.” These react with water and oxygen, forming highly reactive species.

These reactive species are capable of rapidly and non-selectively decomposing harmful organic substances present in water. They break them down step by step into smaller fragments until only harmless end products remain, such as carbon dioxide and water.

From Laboratory Powder to a Practical Solution

Photocatalysts are typically produced in a powdered form. While this works well under laboratory conditions, it poses a challenge for practical water treatment – after application, the powder would have to be removed from the water.

Our goal was therefore to develop a floating composite in which the photocatalyst is firmly deposited onto a lightweight carrier. Such a material remains on or just below the water surface, where it receives the most sunlight and can operate most effectively.

A Three-Component Composite

The powdered photocatalyst, titanium dioxide with particle sizes above 0.1 micrometer, is commercially available, safe for humans and the environment, and highly active in the degradation of pollutants in water.

The photocatalyst is immobilized as a thin layer on the surface of the carrier using a special inorganic binder developed by SChem, a.s. This binder ensures the stability of the composite while maintaining high photocatalytic efficiency.

The carrier itself is made of foamed glass recyclate – an ultralight material that floats on the surface of the treated water for extended periods. It is resistant to degradation, non-toxic, and made from recycled raw materials, thus contributing to sustainability.

Simple Production and Easy Application

The production of the composite is technologically simple, fully scalable, and waste-free. This makes it possible to manufacture the material in larger quantities without the need for complex infrastructure.

From a practical standpoint, handling the material is very straightforward – the composite can be reused multiple times, requires no additional processing steps, and is ready for immediate deployment in water treatment.

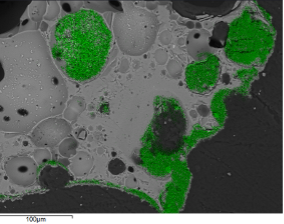

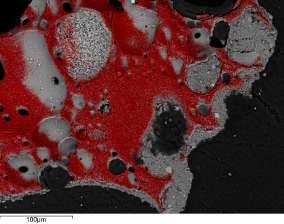

The image shows a cross-section of a porous composite grain captured using a scanning electron microscope. The green color indicates a layer of titanium dioxide (the photocatalyst) with a thickness of 10–30 µm. The red color represents silicon, which in the form of silicon dioxide constitutes the main component of the carrier.